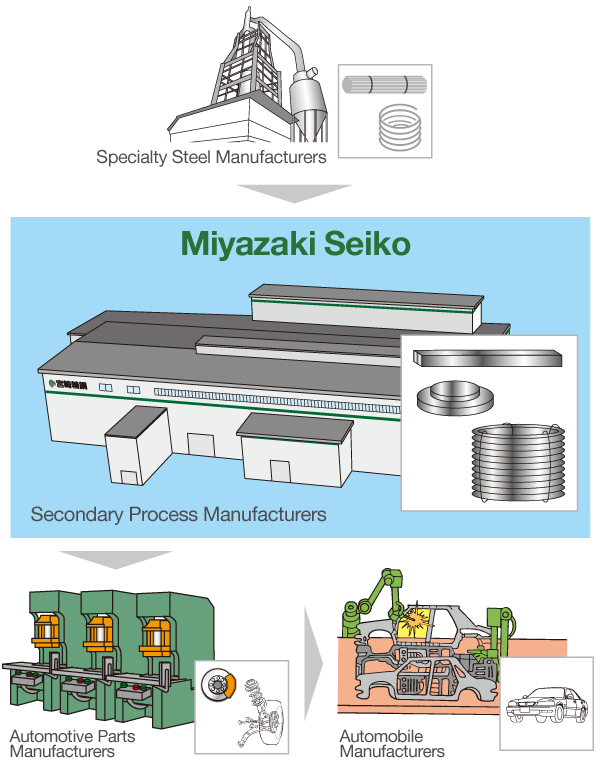

Specialty steels made by primary manufacturers are supplied to secondary processing manufacturers such as Miyazaki Seiko. The secondary manufacturers then process the specialty steels, utilizing various processing technologies, into the different shapes, dimensions and mechanical properties that the customers require to meet the design criteria of their own products.

Miyazaki Seiko manufactures precision cold-drawn bars, pipe in coils, CHQ-wires and fine slugs utilizing such process technologies as drawing, peeling (grinding), annealing, coating and cold forging.